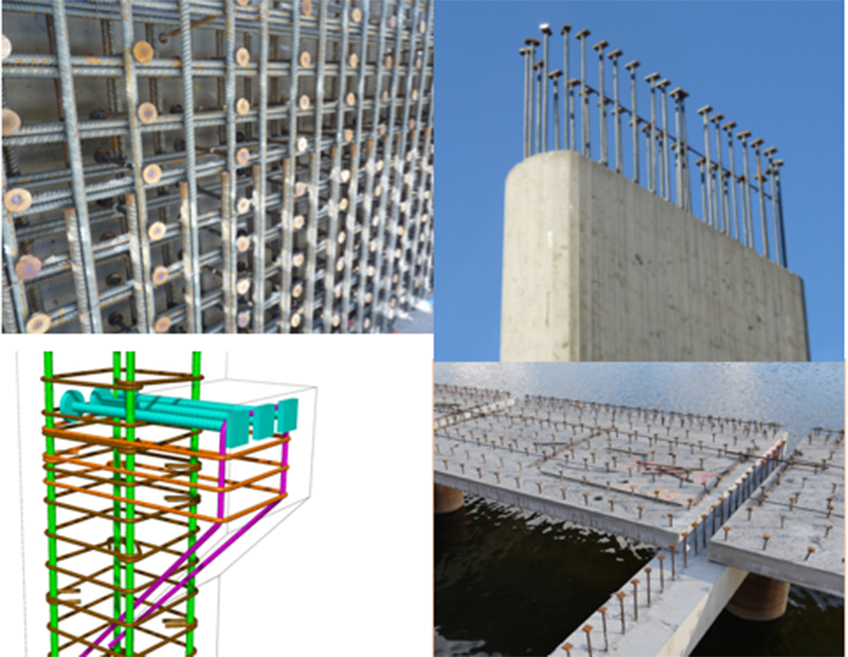

T-headed bars have great potential for optimizing reinforced concrete design and improving the efficiency on the building site.

HRC Europe has for more than 30 years produced and supplied T-headed bars to construction projects, ranging from residential construction, high rise buildings, bridges and tunnels to concrete offshore structures and nuclear installations.

HRC Europe supplied T-Headed bars to some of Europe’s largest construction projects: Metro Copenhagen, Paddington Station London, Hardanger Bridge, Marieholm Tunnel Gothenburg.

Concept of T-headed bars

T-Headed bars are reinforcing steel bars, equipped with a mechanical anchorage in one or both ends. T-headed bars are an alternative to anchoring bends, hooks or lap lengths, providing the shortest possible anchorage length.

Many small-diameter bend bars can be substituted with fewer T-Headed bars with larger diameter. This improves design and constructability.

The non-slip, defined anchorage of the rebar in a point (the T-head) provides an excellent confining effect. This facilitates effective detailing of anchorage zones of pre-tension strands. Tension ties of strut-and-tie models, which are detailed with T-Headed anchorage give good coincidence between model and reality.

Handling and installation of headed bars is easier and faster than bend bars. Especially when used as shear reinforcement where T-Headed bars can be installed up to 5 times faster

HRC has BIM-components (Tekla, Allplan, Revit).

High performance

HRC 100 Series T-Headed bars are designed and produced to develop the full actual tensile strength of the rebar. No additional anchorage length is needed, and the full ductility of the rebar is developed. This is very important for the robustness of a structure – and can make the difference between survival or collapse in case of extraordinary load scenarios, like accidents or natural disasters.

The newest development of HRC are HRC150S stainless T-Headed bars which can be combined with both stainless rebar or “black” carbon rebar.

Certification and environmental aspects

HRC Europe is certified acc. to ISO 9001 and ISO 14001.

HRC100 Series T-headed bars are certified to the product standard (ISO 15698), documenting their ultimate capacity and the suitability for structures designed for earthquake loads. HRC100 T-headed bars are covered by a European Technical Assessment (ETA) and bear the CE-marking. The latter is the visible sign that the products can be used in all European member states.

The product performance and certification level fulfill the requirements to Boverket BBK and AMA Anlägging.

HRC T-headed bars have a positive environmental impact due to reduction in rebar weight and by providing reduced construction time. HRC T-headed bars are fabricated with recycled steel and are covered by an Environmental Product Declaration (EPD), which is Approved by The International EPD System in Sweden.